There are two types of wire construction when it comes to twisted-pair network cable: stranded and solid. There are connectors designed to target these specifically (although some claim to handle both).

I have found that while being able to identify the cable and its purpose is fairly well known, identifying the connector type is less so. Here’s what I have found from experience…

Cable type

First a quick run through of the cable itself.

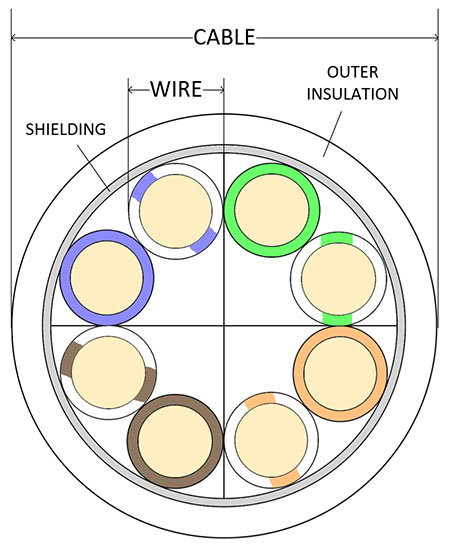

When I say cable, I mean the whole assembly; all of the wires, any shielding, the outer insulation, etc. Wire refers to the single conductor within the cable. Like so:

Stranded

Stranded core cable has wires that have multiple strands of conducting material (hopefully copper!) in each. This allows a more flexible cable as the thinner strands can move around while being bent without needing as much force. It’s more durable for situations that need this flexibility such as temporary connections and for equipment that moves.

The connectors for stranded core cable generally work by wedging the pins through the strands of the wires. The pins often have a fairly blunt shape to them and don’t splay out at all. As long as the pin can break through the conductor’s insulation, then the strands surround the pin and maintain contact.

The above has a much deeper wedge than what I’ve seen for a stranded connector; I suspect it is one of the connectors that is marketed to handle both types of cable. It shows the general shape of a stranded connector though until I find a stranded connector to photograph.

Solid

Solid core cable has wires with a single conductor in each. It is less flexible and is usually used in fixed installations such as cabling in walls and ceilings. Solid conductors have a higher cross-sectional area compared to stranded of the same diameter which means lower resistance.

The connectors for stranded core cable generally work by cutting into the edges of the conductor and wedging it between the prongs of the pin. It looks sharper, and usually has 3 prongs that are offset for the conductor to sit between. This works the same as a punch-down connector or block (IDC = insulation displacement connector).

Mixing the two

So what happens if you use the wrong type?

Generally you can get away with using a solid core connector on a stranded core cable. It’s not ideal, but I haven’t really seen instances of it failing.

What I have seen issues with is a stranded core connector on a solid core cable. It will usually work for a while, but then becomes flaky or loses connection entirely. I believe this is because the pin doesn’t have any consistent pressure maintaining the contact which loosens slightly over time. The proper connector maintains the connection with the combination of cutting into the conductor and the elasticity of the prongs.

I have seen connectors marketed as being suitable for both. From what I have seen, they look more like stranded connectors than anything, but haven’t used them enough to comment on their long term effectiveness.